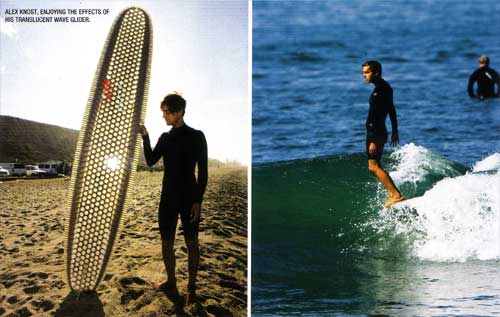

Mike Sheldrake has never felt the power of a planer or scrubbed foam with a sanding block or even stenciled his name on a redwood stringer. Short of fixing a ding or two, he is a man with no surfboard trade skills. None. But he is a man with the gumption to put his dreams into action. The end result: a cardboard-core surfboard. "I got to thinking about building my own board and hollow boards looked pretty cool," explained Sheldrake. "I thought about what I could do with a computer to help the process along. I thought cardboard would be a good modeling material, but I also knew that cardboard might be more than just a beta material, due to it's obvious lightweight." Sheldrake did lots of research on the Internet. He looked to aerospace blogs for insight into the strength-to-weight ratio as it relates to design and how to graphically manipulate lines and rib interactions for his cardboard cores. "I'd look for the math that explained how to apply curves using programming language. I was researching aerospace design more than any Tom Blake stuff," explained Sheldrake. "It was all very nerdy." His first board design was a crude template taken from the tail of a favorite 7-foot egg and spliced into the upper-half of a Robert August noserider. Sheldrake continued to tweak the measurements so that the curve flowed properly. Eventually, he was pleased with the outline and rib intersections enough to have it cut out. Sheldrake then called in a few favors. His brother knew a buddy at a stone-cutting company in Oregon. Sheldrake flew up to pine country to cut out his cardboard-core surfboard using the stone company's laser cutter. Before him lay the pieces to his surfboard puzzle. Now Sheldrake had to put them together. "I shipped them home, stuffed them in a suitcase, and glued them back together back here in SoCal," explained the 32-year-old. "I assembled it and glassed it up and it turned out really ugly and lumpy. Sort of hideous really, but it had promise." Sheldrake continued on his quest to make the perfect, or at least formidable, cardboard-core surfboard. Months of design tweaks and experimentation with glassing took place. "I'm trying to keep the process low-tech and inexpensive so the tools are limited on purpose. I don't want to spend thousands of dollars on production technology," explained Sheldrake. "I want the regular Joe to be able to do this." To his credit, Sheldrake has made lots of progress. So much so that Alex Knost saw one of his cardboard creations at Newport Beach and immediately ordered one. According to Knost, the board rides unbelievably well. Sheldrake admits that there is a long way to go before the cardboard core is a staple of any quiver. "There are lots of weight issues and laminating problems and just the economic viability of a production facility still needs to be worked out," explained Sheldrake. "But I'm on to some cool ideas, and half the fun is figuring all that stuff out."

Weight, flex, and production issues aside, the mere fact that a surfer with a vision and enough moxy to act on his dream has produced an interesting and unique new core is to be commended. Cardboard! Who knew? Grubby Clark must be shaking his head. |